The Internet of Things (IoT) has revolutionized the way manufacturing industries operate. Manufacturers worldwide now integrate IoT devices with their existing industrial processes to increase efficiency. These devices are partly created by embedded software development experts, and they help manufacturing companies outperform their competition.

Technological advancements give consumers access to products developed in different countries worldwide. However, manufacturers must work faster to meet the global product demand, and IoT is crucial to that effort.

What is Internet of Things (IoT)?

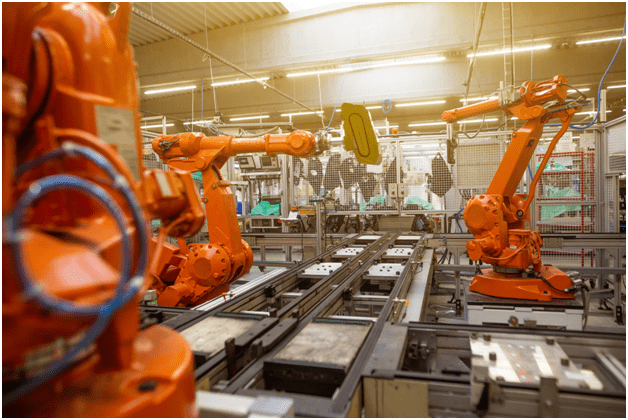

IoT is a collection of interconnected devices that communicate with each other through the internet, cloud computing systems, and other forms of network connectivity. These include near-field communication (NFC), Bluetooth, and wifi. Some common examples of IoT devices are motion sensors, thermostats, smart lights, and robotic arms. In manufacturing, IoT becomes IIoT – Industrial Internet of Things, where devices, sensors, and applications work together to increase productivity and energy management.

These devices rely on embedded software development to function as intended. Manufacturers can work with specialized companies to create embedded software for IoT devices tailored to their operations. Most industries need the following to digitize their operations successfully:

- Cloud computing systems to process and store data.

- Smart devices with embedded software that can generate and process data.

- Data analytics systems that can interpret the data generated by IoT devices.

- Skilled employees who can use the generated data to improve industrial processes.

How IIoT Improves Manufacturing

Manufacturers that correctly integrate IIoT with their industry operations will benefit in the following ways:

More efficient manufacturing

Manufacturers can use IoT devices to automate specific tasks. Robots and automated machinery are more accurate than humans and can work hours without a break. This increases productivity while reducing labor costs. Also, the embedded software in these types of equipment will allow people to gather operational performance data to optimize them where possible.

Faster product delivery to market

Industrial IoT devices increase manufacturing efficiency, so products are produced and shipped out faster than usual. This allows retailers to restock their shelves quickly, reducing the time consumers wait to get their desired products.

Proactive maintenance of equipment

Manufacturers can proactively schedule their maintenance by using the operational performance data they collect from Industrial IoT devices. This prevents equipment downtime which slows down production, causes unplanned expenses, and makes manufacturers miss out on potential sales.

Safe conditions for factory workers

IoT devices like cameras, motion sensors, smart alarms and smoke detectors create a safe working environment for factory workers. These devices can be programmed to stop moving parts, quench fires, alert workers, and perform other safety actions to prevent loss of life or body parts.

Endnote

The Internet of Things benefits the manufacturing industry and can help companies make more money with fewer human resources. Manufacturers can use IoT devices to automate crucial processes while collecting data that they can use to optimize said processes. They can use the insights they gain from the data to proactively maintain their equipment, accurately plan logistical operations, ship out products faster, and protect their workers. These will make companies outperform their competition and become more reliable to consumers.