A car alternator is electric power generator of your vehicle. It is the main source of your automobile power system. The main task of the alternator is to charge continuously the car battery when your car is running. There by, it supply adequate power supply to your vehicle electrical and electronic parts, without straining your automobile battery.

What is an Alternator?

It refers to an electrical generator. These help to transform mechanical energy into electrical energy. It converts the energy in the form of alternating current. Usually, we call an AC electrical generator an alternator. But it indicates the small rotating machines actually.

Working:

It may seem to you that the battery is the one that powers the electricity in any car. But it doesn’t happen actually. The battery delivered the required electricity to the starter motor. It helps to start the car. The car alternator creates electrical energy while the car is running. It assists in charging the battery and feeding the electrical system. It is also known as a generator as it works in similar way. Moreover, the car’s internal combustion engine helps to spin pulleys. The whole assembly remain under the bonnet. It helps to turn the pulley of the car alternator. And thereafter, it helps to generate required electrical energy.

The car alternator usually works hand in hand with the battery to supply energy for the vehicle’s electrical instruments. Direct current (DC) is the car alternator output. AC or alternating current passes through a magnetic field in this case while you rotate the car alternator pulley. When the AC passes through the magnetic field, an electrical current is generated. Then, the rectifier converts the AC to DC.

The automobile use them to create the electric current. And it is an external regulator helps to control the flow of current. In previous days, the built-in regulators used the warning lights. It is because these assist the alternator and begin the charging procedure. Nowadays, modern vehicles use a load request type charging system and smart charge systems and CANBUS systems. The vehicle Engine Control Unit (ECU) controls the system. If the vehicle demands more load, the ECU helps to send a signal to the car alternator. The signal here is sent as a request to start the charging process. Hence, the alternator needs to tolerate varying electrical loads. And according to the load, it has to adjust the charging rate.

Types and Classification:

You can classify alternators or synchronous generators in multiple ways. It relies on its designs and applications.

There are five different types-

Automotive Alternators: People use these in modern automobiles.

Diesel-Electric Locomotive Alternators: These are mainly used in diesel-electric multiple units.

Marine Alternators: These are used in marine applications.

Brushless Alternators: People use these as the main power source in electrical power generation plants.

Radio Alternators: You can use these for low band radio frequency transmission devices.

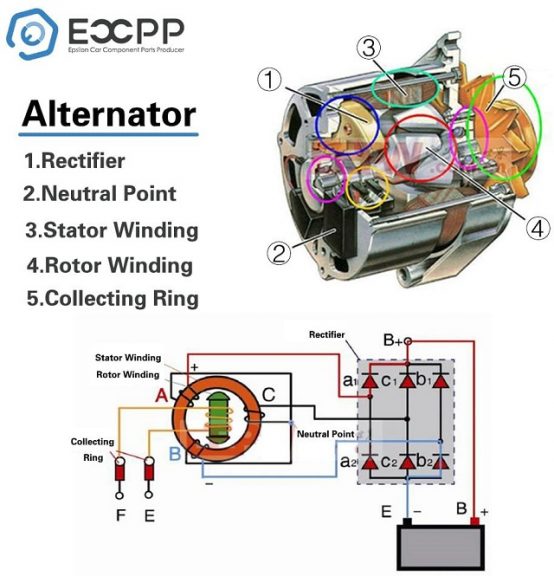

Major Parts of a Car Alternator

You can get the old models at reasonable prices. They are available at automobile wrecking yards. Most of the yards offer those; which are discarded from automobiles already. Therefore, you should not pay the full amount to buy a new one. It is because the used units cost very less and solve your problem as well. You can use the Delco-Remy brand in this case. People use it in general motors such as Buick, GMC, Cadillac, Chevrolet, Oldsmobile, etc. Most of the people buy it in a second hand shop. Delco-Remy is very user-friendly.

However, you can use two alternators also. Then, you need to use one as a motor and another as a generator. You can follow a three-phase motor’s setting, process similar to the three-phase generator’s preparation process.

Car Alternator Wiring Diagram

An automotive alternator refers to a three-phase car generator. It includes a built-in rectifier circuit that consists of six diodes. Here, a belt helps to rotate the pulley. And this belt is attached to the crankshaft of the engine. There exists a magnet also that spun past the stator. It is a combination of three-phase windings. That is attached as a Y configuration.

The spinning magnet used here is an electromagnet. The car alternators come in such designs that allow you to control the magnetic field strength. It helps to control the output voltage when rotor speeds. The rotor magnet coil is known as the field coil. It gets energy from the power of the battery. This one takes little power input from the alternator. After getting the input power, it can create a huge amount of output power. Here, the rotating field coil helps to conduct electrical power. Copper “slip rings” is helpful in this case.

Multiple latest models of alternators are there that contain built-in “regulator” circuits. The circuits power on and off the battery automatically to regulate the output voltage with ease.

You can easily remove the circuits. But while doing this, make sure that you are leaving access to the brush terminals. By doing so, you can provide more energy to the field coil.

Car Alternator Checking Instructions:

Step. 1

Your first task is to go through an automotive repair manual to get detailed knowledge. A service manual can give you more specific details. To experiment, first, attach the wires to those coils that are available in the car alternator. And connect it in such a way so that you can extend the wires outside. Thus, the experiment will become easier for you. While going through the process, make sure that you have taken the right connection terminals.

Step. 2

Now, you need to find the correct terminals after disassembling the unit. By doing so, you can attach it with two carbon brushes. Then, go for the soldering process. You need to solder two wires to the terminals. But use such terminals wires that are 20 gauge size at least. After that, extend them via vent holes. You need to do it so that the wires don’t get fastened on the motor.

Step. 3

You have to point to the three-phase line connections now. The stator windings are the source from where these connections come. Then, attach the wires with these. While extending wires through vent holes, you always need to use the biggest gauge wire. It makes your work easier. If you are using field wires, then you have to route these. But do it in such a way so that the rotor will get full access for a free turn. So, you can use the stator winding line terminals.

It is because you can locate these with ease. These three types of wires are attached to the three terminals. The terminals you should use here are “ring-lug” terminals. It is better to solder these terminals to the wires. Then, you can connect these with terminal nuts and the end part of the stator. You should do it because each diode block terminal comes with two ring lugs.

Step. 4

Now, you need to reassemble the car alternator. You need to keep the carbon brushes securely and in a retracted position. You can use the Delco-Remy brand. It comes with a little hole available on its back case half. You can find the hole on the front side of the brush holder. The holes allow you to insert thin-gauge wire or a paper clip. By doing this, you can hold it back against their spring pressure. Take suggestions from the service manual to know more.

Go for spinning the shaft. But do it only when you assemble the car alternator. Check if any sound exists from colliding parts or snagged wires. In case you get any sound, then fix it. When this one spins freely, attach a pair of “field” wires with a 6-volt battery. Now, you can use a voltmeter and attach it to any two-terminal of three-phase line connections.

Step. 5

When you have a multimeter set, you can rotate the alternator shaft slowly. You can see the reading of the voltmeter alternating from positive to negative. Hence, a slow AC voltage is produced. Now, you can use the multimeter for “AC volts”. You need to spin the shaft slowly.

Next, you need to choose any two wires of the three-phase line. And then, spin the alternator again. Now, you can find the shaft harder for spinning. Hence, the short circuit generates a heavy electrical load. And then, it turns the load into a heavy mechanical load.

Now, use the 12 volts DC and attach it with field wires. Again, undergo all the tests— DC voltmeter, AC voltmeter, and short-circuit tests.

Step. 6

Look for a polarity-insensitive load. A tiny incandescent lamp can make your job done easily. You need to attach these with three-phase line wires. Now, use a thin rope to wrap the pulley. Next, your job is to spin the car alternator.

If you want to use another alternator, undergo the modification procedure as previously.

List of Best Car Alternators

Here, we have listed the names of the five best alternators. Check out these.

- ACDelco 335-1086 Professional

- DB Electrical AFD0110 Aftermarket

- Reman

- Premier Gear PG-7791

- Quality Built 7078107

5 Best Car Alternators

-

ACDelco 335-1086 Professional

The ACDelco 335-1086 Professional consists of 100% high-quality and upgraded components and parts. It is a good quality product. The product is durable and long-lasting. As the parts of the ACDelco 335 are made of superior components, you can also use them in harsh conditions. You can test the new parts on a computer for checking the voltage stability. Besides, you need to check it for electronic circuit board integrity, as well as terminal functionality.

The ACDelco 335-1086 Professional consists of 100% high-quality and upgraded components and parts. It is a good quality product. The product is durable and long-lasting. As the parts of the ACDelco 335 are made of superior components, you can also use them in harsh conditions. You can test the new parts on a computer for checking the voltage stability. Besides, you need to check it for electronic circuit board integrity, as well as terminal functionality.

The ACDelco 335 is of ISO Quality Standards. 105 A is the amperage rating of the product. It can last for a long time. All credits of the product should go to the advanced engineered internal parts. There is a Serpentine pulley belt system which helps the product to run efficiently. It is ubiquitous in gasoline-powered vehicles.

Awesome Features:

Performance: To improve performance, the parts of the product come with new technology and upgraded components.

ISO Quality Standards: ACDelco 335 is manufactured following the rules of ISO Quality Standards.

Efficiency: The internal accessories are engineered in such a way so that it can deliver an efficient unit to your car.

Pros:

- Efficient enough

- The serpentine pulley belt system

- ISO quality standards

Cons:

- Faulty internal voltage regulator

DB Electrical AFD0110 Aftermarket

Description: The manufacturer of DB Electrical AFD0110 Aftermarket is a renowned aftermarket brand. People who have Ford and Lincoln model cars can use it only. The product comes with a one-year warranty. It means that you can return it to the manufacturer within the first 12 months if you face any problem with the product.

Description: The manufacturer of DB Electrical AFD0110 Aftermarket is a renowned aftermarket brand. People who have Ford and Lincoln model cars can use it only. The product comes with a one-year warranty. It means that you can return it to the manufacturer within the first 12 months if you face any problem with the product.

The product is an aftermarket alternator. The product weighs and comes with a brushed exterior. The dimensions of the product are 5.71 “× 4.91″ × 5.05”. The amperage rating of the product is 110. And the voltage is 12. It rotates clockwise.

Awesome Features:

Performance: The brand always produces such items that can work in high-heat environments. The premium materials that are used to the product make it unbeatable in the market.

Construction: The high-quality bearings, along with heavy-duty rectifiers, make the product exceptional. Such a configuration helps to make the product durable enough.

Additional Features: The superior quality grease and High-temperature epoxy make the product heat resistant. Even, it has similarities with OE originals. DB Electrical AFD0110 Aftermarket comes in a true-fit design which makes you sure that it fits effortlessly. You can use this product in all kinds of vehicles to get flawless performance.

Pros:

- Fast delivery

- Heat resistant

Cons:

- Not so long-lasting

Reman (2100580)

Description: It comes with a 130A amperage rating. This Reman (2100580) contains rotor slip rings. The limitation is a maximum of twenty microns hence. Therefore, there doesn’t exist too much wear on the brushes. Therefore, you can use Reman (2100580) for a long time.

Description: It comes with a 130A amperage rating. This Reman (2100580) contains rotor slip rings. The limitation is a maximum of twenty microns hence. Therefore, there doesn’t exist too much wear on the brushes. Therefore, you can use Reman (2100580) for a long time.

It goes through over 29 various performance and safety checks. This product is durable enough. Reman (2100580) supports plenty of different famous vehicles. For example, it supports the 2008 Honda Ridgeline, 2008 Acura MDX, 2008 Acura RL, 2006 Honda Odyssey, 2006 Honda Pilot, and 2003 Acura MDX.

Awesome Features:

Effective: The product comes with the highest quality replacement parts. Besides, the manufacturers used lubricants of OE-standard to make this product unbeatable.

OE-Standard Quality: Each core undergoes a rigorous quality control process. So, the manufacturing didn’t comprise even a little bit while manufacturing the product. When it comes to quality, no product can beat it. This one contains the finest re-manufactured parts.

Pros:

- OE-standard quality

- Efficient performance

- Compatible with 2008 Acura RL, 2008 Honda Pilot, 2006 Honda Odysseyz, and so on.

Cons:

- A few users reported that only after a few months of usages the volt regulator failed.

-

Premier Gear PG-7791 Professional Grade Alternator

Description: This one is a professional grade alternator. When your vehicle fails to start or is unable to overcharge, then this Premier Gear PG-7791 can come to your help. The advanced protection of Premier Gear PG-7791 helps to solve this problem. In case there occurs a short-circuit, this product can protect against this situation.

Description: This one is a professional grade alternator. When your vehicle fails to start or is unable to overcharge, then this Premier Gear PG-7791 can come to your help. The advanced protection of Premier Gear PG-7791 helps to solve this problem. In case there occurs a short-circuit, this product can protect against this situation.

The Premier Gear PG-7791 Professional Grade is perfect for those who want a model that can last long. It is made of high-quality components. This one features premium brushes and an internally regulated fan.

Awesome Features:

Protection: It doesn’t allow your vehicle from over charging. This one gives you protection against the short circuits.

Performance: It can deliver awesome performance continuously. The bearings, wiring, and components of the product make it heat-resistant.

Long-Lasting: It comes with key components and premium brushes that make the product long-lasting.

Pros:

- Superb performance

- Premium brushes and regulated fan

Cons:

- Doesn’t last for an extended period.

-

Quality Built 7078107 Alternator

Description: The Quality Built 7078107 is very famous because of its brand name. It undergoes an extensive re-manufacturing procedure. Besides, the product undergoes different quality control tests such as root cause analysis and durability tests.

Description: The Quality Built 7078107 is very famous because of its brand name. It undergoes an extensive re-manufacturing procedure. Besides, the product undergoes different quality control tests such as root cause analysis and durability tests.

It is designed with the latest components and parts. These parts make the product long-lasting.

Awesome Features:

Build Quality: The Quality Built 7078107 undergoes a re-manufacturing procedure that makes it very reliable.

One Year Roadside Help: The manufacturers offer one-year roadside assistance on the product. Besides, it comes with toll-free Quality-Built Technical Support.

Pros:

- 1-year roadside assistance

- Awesome build quality

- Undergoes control tests

Cons:

- A few users reported that the product is unable to work properly.

Uses of Alternator

It provides the more power for the electrical system that is needed to start the engine. In the early days, people used DC generators or dynamos. But in this developing era, we use a robust and lightweight alternator. In most cases, direct current is essential for the electrical system of motor vehicles. But still, people prefer to use an alternator with a diode rectifier. It is because there is no complicated commutation. This kind of generator is known as an automotive alternator.

Besides, it is also used in diesel-electric locomotives. The generator here creates an alternating current. And then, the integrated silicon diode rectifiers convert it to direct current. The DC traction motors assist in driving the locomotive wheel.

How an Alternator Can be Tested

Method 1: Using a Voltmeter

Buy a Voltmeter:

First, you need to buy a Voltmeter. It is available in auto parts stores. You can get it for less than $20. Don’t buy a costly one. Try to buy a cheap voltmeter as it can get your job done. However, a Multi-meter is also suitable for this purpose. These can measure voltages along with other electrical properties like current, resistance, etc. While checking the alternator, you need to measure the voltage.

First Check the Battery:

When you start your vehicle, you first need a battery. It rotates the alternator at a proper speed so that the battery can remain charged. Therefore, you can’t start your car when the battery is about to die. However, the battery can also create issues when the weather is cold. An old battery also creates problems. That’s why I always check the battery before checking the alternator. Here, we have given the method of how you can do it.

- First, you need to power off the car. Before attaching the voltmeter, make sure that you have turned off the engine.

- Then, you have to open the hood.

- After that, you need to make a connection with the voltmeter and battery.

- Then, your job is to connect the red point of the voltmeter with the positive terminal. And then, add the black lead to the battery’s negative terminal. Hence, make sure that your skin must not touch the battery.

- Then, you have to read the voltmeter level. If the reading of the battery comes above 12.2 volts, then it is enough to start it. After that, you can test it with the help of a voltmeter.

In case the battery doesn’t have sufficient voltage, then charge the battery and test again. You can go for a different process to check it.

Try Starting Up Your Vehicle:

Now, you need to start the vehicle. And then, gear up the engine to 2,000 RPM. It helps to increase the charging rate of the battery. As a result, the voltage regulator can easily kick the alternator into high gear.

Keep the Engine Running and Test the Battery Again:

At last, you need to keep the engine in running condition. And then, you have to test the battery again. You need to use the voltmeter now. While measuring the voltmeter’s reading, the voltage must go at least 13 volts. Sometimes, voltage fluctuates between 13 and 14.5 volts due to the variable RPMs. If it happens, make sure that the alternator you have is in good shape. On the other hand, if it doesn’t work properly, the voltage will decrease or remain the same. Now, do the same method with the lights, radio, and AC on. The alternator is charging when the voltage remains more than 13 volts and the engine at 2,000 RPM.

Method 2: Monitoring Your Alternator

Check Gauge: You can use a volt or amp gauge hence. It will help you to read the output of the alternator. Hence, you have to run the engine at 2,000 RPMs while testing. You need to switch on the blower fan, the headlamps, and other accessories—this helps to strain the alternator. Then, you have to see the gauge to check whether it reduces the voltage or not. You can make sure that the alternator is charging when the voltage is high at the running condition.

Listen to the Alternator While the Engine is Running: You can hear a squealing sound from the front side of your car. If it happens, make sure that the bearings are creating problems. The sound becomes louder by using power simultaneously.

Power on the Radio and Rev the Engine: Now, you need to turn the radio to a low number. In case you find the radio going fuzzy every time you hit the gas, the culprit is the alternator.

Find an Auto-Parts Store that Tests Alternators for Free: Usually, most stores want the customers to buy from them. And to do it, a few shops offer free testing to edge-up their competitors.

How an Alternator Can be Replaced

- First, you need to save the memory on the preset electronics of the vehicle.

- Then, disconnect the negative battery cable.

- After that, your job is to loosen the tensioner of the belt.

- Then, discard the serpentine belt. But before doing it, you need to loosen the belt.

- Next, eliminate the connectors or the wiring harness.

- Now, you have to loosen and remove the alternator.

- After that, go for the installation procedure of the latest one. But ensure that it will both fit and align with the bolt holes.

- Next, you should put on the replacement belt. While doing it, see the connection of the belt to check whether it is correct or not.

- At last, reconnect the negative part of the battery cable.

Automobile Alternators Components

The focus of automotive alternators’ components is to offer the correct type and amount of power to the vehicle. There are usually plenty of components in your vehicle’s charging system. But here we have named only a few main components.

Rotor and Stator:

These are the components that are used to produce electricity. The rotor has a cylindrical shape. Magnets surround it. The rotor spins inside the stator. Hence, the stator holds multiple conductive copper wiring. It is the movement of the magnets, which helps to produce electricity.

Voltage Regulator:

The function of this component is to oversee the power made by the alternator. Here, the voltage level refers to the battery output. The regulator helps here to monitor the voltage level. Besides, it also helps to deliver power to the rest of the electric components of the vehicle.

Diode Rectifier:

It helps to convert the voltage in such a form that the battery can recharge.

Cooling Fan:

Alternators usually create huge heat. That’s why you need to cool these for operating proficiently. These fans consist of vents and aluminium casing. This construction helps to release and transfer heat easily. There are also rotating fans that offer added cooling. Nowadays, the latest models come with internal cooling fans. However, the old models had external fan blades.

What Does an Alternator Do?

The car alternator function is to provide electricity to your vehicle. It helps to recharge the battery. But for doing all these things, it needs to convert the mechanical energy into electricity.

How the Alternator Produces Electricity?

The method to generate electricity starts with the engine. In most modern vehicles, the engine’s crankshaft helps to drive the alternator. In this case, it uses a serpentine belt. However, you can find a separate pulley in the older models. The belt’s movement, along with the mechanical energy, helps to spin the rotor at high speed.

When the rotor starts spinning, electricity produces. Hence, the magnets are placed in such a way so that these can pass over easily the copper wiring. You can find the copper wiring in the stator. The magnets help to create a magnetic field also that generates a voltage. After that, the stator captures the voltage. The power helps to reach the voltage regulator that can disperse electricity to your car. And then, it manages the amount of voltage received by the battery.

How to Charge the Battery?

You need to convert the power to a form that the battery can use. It is the reason why electricity flows in different currents or directions(AC or DC). The car batteries usually use one-way direct current (DC) to operate. On the other hand, the alternator’s output alternating current (AC) flows in reverse sometimes. That’s why you should go to the voltage regulator. It goes through a diode rectifier for converting it into DC. The battery can take the help of the power to recharge.

Car Alternator Repair Process:

Here we have given the easiest alternator repair process. Let’s check it out:

- Before starting this method, make sure you have bought a brush and regulator replacement kit required for the user model.

- Now, for safety purposes, you need to disconnect the car battery.

- Now what you need to do is remove the alternator.

- After removing the alternator, your task is to remove the rear cover on it.

- After that, you need to remove the old regulator and brushes. Then your task is installing new brushes, and reconnecting wiring, and refitting bolts.

- Now, you need to refit the rear plastic cover.

- Now, fit the alternator back. But you need to confirm that the alternator belt is tightened enough.

- Finally, you need to check whether you have fixed it properly or not.

Characteristics of Alternator:

The characteristics of alternators are as follows:

Output Current with Speed: It depends on the speed of the alternator. It reduces or decreases along with the speed deduction of alternators.

The efficiency with Speed: Efficiency is decreased while it runs at a low speed.

Current Drop with Increasing Temperature: The output current will get decreased with the increment of temperature.

Warning Signs of a Bad Alternator:

Usually, a defective one shows plenty of symptoms. When you become familiar with these symptoms, you can spot the issues effortlessly. Here we have mentioned a few alternator problems and symptoms. Let’s check it out.

Indicator Light Illuminate on Dashboard

You can see warning indicator lights in plenty of cars. These are present on the dashboard as ‘ALT’ or ‘GEN’. You can find them also in the shape of a battery even. If you see it flashing, then ensure that it has an issue. The light has a connection with the computer systems of your vehicle. The computer helps you to monitor its output voltage. You can get high output or under a preset limit. At that time, the dash light triggers automatically. When the alternator’s output comes in the average or normal range, the dash warning light also becomes normal.

However, sometimes the dashboard warning light can be flickered. This may seem at the first stage of car alternator problems. The variable voltage output may be the reason for it. While using more power, you can even see the light flashing. You can check it while driving at night. Sometimes, you may feel cold while driving at night. So, if you want to flick on the heated seats, then your vehicle requires more energy. In case you are unable to do it, make sure that there is a problem with the alternator.

Remember that you must not avoid it when you see the ‘ALT’, ‘GEN’ or battery shaped lights give you warnings. Even if the lights only flicker on, then also you should not avoid it. In case you ignore, it can cause you expensive repairs. That’s why you should go to a garage for servicing. If you go to the garage very fast, the mechanics can diagnose the problem quickly. And they can solve the problem if it is in the first stage.

Dim/Flickering of Headlights

The dim headlights can cause the issues also. When the RPM becomes high, the lights also become brighter. And the brightness of the light becomes low when the RPMs fall. If it happens, you can ensure that the alternator can’t produce more power. It becomes unable to meet the electrical needs of your vehicle. The symptoms rely on multiple factors.

But the factor that is vital how the vehicle is programmed. It is because, in recent times, most of the vehicles come with pre-programmed features.In addition, It entirely depends on the safety considerations. Moreover, It indicates that all the heated seats or radio won’t work more. These will stop working when the headlights are going to fade. It is a safety feature; hence, you don’t need to repair the alternator while the headlights become faded.

Dead Battery

When you are going to start the car, you may hear a clicking sound. It is a sign of a dead battery. A dead battery can be the sign of a failed alternator. However, it won’t happen every time. If the alternator fails, this becomes unable to deliver sufficient current to your vehicle. The batteries of the cars are designed in such a way so that these can deliver the starter motor enough power. It can’t offer a regenerative charge to the battery if the alternator is unable to work. That’s why you should check the alternator whether the battery is dead or not.

You can even check the battery gauge. It is available on the dash that helps you to assess your vehicle’s battery state. In case you find these delivering still a strong charge, there is less possibility of battery problems.

There is also a method that lets you know which one creates the battery or alternator. Hence, jumping start your vehicle can be a nice way. But remember your vehicle won’t work when the alternator falls. If you see that the car is still running, then the battery creates a problem.

Strange Sounds

Strange sounds can be a warning sign. It can indicate the car issues. And you may face difficulties in determining the source of the sound. Whether you hear any kind of strange sounds, then make sure that the problem is in alternators.

If any parts of your vehicle will break, then you will get grinding sounds. On the other hand, you can get the whining sounds. It is when the voltage regulator will notify the alternator that it needs more charge.

Strange Smells

Sometimes, you can get a strange smell that usually comes from the bonnet. Different types of smells are there which you can get. The main reason for the smell is the hard-work of the alternator. When you get a smell of hot wire or electrical fire, then the reason is the alternator is overheated. In case you get a smell of burnt rubber, then make sure that the rubber belt is not turned freely. It results in excess friction because of which the belt heated up. This make it smell like a distinctive burning rubber.

Slow Electrical Accessories

Problems in the accessories are also the reason as we have discussed earlier already. When the electric windows operate slowly, or the heated seats won’t work, or the radio operates erratically, you can make sure that the alternator failure is the reason.

Advantages:

These come with some advantages that the generators don’t have. Here, we have discussed the three benefits. Check these out.

- Higher output

- Lower weight and smaller size

- Less maintenance

Higher Output: The components or the parts are compelling compared to the parts of the generators. Therefore, the parts allow it to rotate too quickly. Thus, the risk of damage will get reduced. If these have a higher rotation speed, then these can create more power very easily. The higher rotation speed also indicates that it can generate extra energy at lower speeds. It helps you to get charged while your car is idling even.

Lightweight and Smaller in Size: It can produce electricity effortlessly that can offer you two distinct advantages. If you have a lightweight car, then it consumes less fuel. It helps you to save money easily. And the second one is that it comes in small sizes. Therefore, it is easily fitted even in the crowded engine compartment also. It helps to make your work easier during the maintenance and repairing time.

Maintenance Free: These come with brushes and a system of rings. Both of these help to create electricity. These use solid rings instead of split rings.

Disadvantages:

The drawbacks are as follows:-

These don’t have any transformers.

When the current is high, it becomes overheated.

How Long Does an Alternator Last?

It can last for about seven years. The main function of the battery is to start the car. And then, the alternator helps to keep it in running condition. Usually, it can last about 100,000 to 150,000 miles. It is also said that a few models can last about 80,000 miles.

How Much Will it Cost to Replace an Alternator?

For the alternator replacement, the average cost will be $400. Again, a re-manufactured one on a typical, domestic car will cost approx $300 to $500. The price includes all the parts and labour. You can go for a new one also. The alternator price starts from $500 to $1,000.

How to Make Your Alternator Last Longer?

You can replace some components before wearing them out. By doing so, you can prevent these from heat, vibration, and contaminants. For example, a few manufacturers are there in the market who ask to check the regulator and brushes in each 12 to 24 months.

Alternator vs Generator:

Both offer the same results (electrical power). However, a few points are there that differ between these two technologies.

An alternator is unable to provide charge to a drained battery whereas the generators can do that. Using an alternator can cause an explosion when you charge a drained battery. That’s why you should take safety precautions. Generators can create direct and alternating current both. But the other one can create alternating current only.

That’s why people who require direct current should use the generator only. The direction of the current changes in each half rotation of the rotor. And during this period, the AC is generated. The end part of the circuit has a direct connection with the load. It helps to produce the alternating current. If you want direct current, then you need to attach the wire with the commutator. It assists in delivering direct current by converting it from AC.

Sizes and Design-

These come in different sizes also. Generators are larger compared to the other ones. You can fit the alternators in small areas due to their small size. But the generators need large spaces to keep.

The interior design also differs between these two. A generator usually comes with a stationary magnetic field whereas you get a rotating magnetic field in the other case.

You can use alternators easily. Due to this, people use these in their cars and commercial electric power plants. But the generators can be used in many services. People can use the generators as DC motors. Hence, they apply power to the shaft. When you discard the shafts, it will work as a generator. However, you need to use additional circuitry while using an alternator to convert AC to DC. This extra circuitry will make the design complicated.

Alternator Parts and It’s Functions-

A generator gets power from a rotor, whereas the stator supplies power to the other one.

Again, a generator usually consumes all amount of energy generated, and because of this, the generators conserve less energy. On the other hand, the other one takes only that amount of power that is required. Thus, these help to conserve more power.

You need to polarize the generators when you install. But in the other one’s case, you don’t need to polarize. Again, the difference between the two is that the generators offer fewer amounts of output than others.

These also differ when it comes to the power generation process. This power generation method for generators is very less efficient compared to the other one. Each of these follows the law of Faraday of electromagnetic induction. For generators, wires spin inside a magnetic field. But for the alternator, a magnetic field spins inside the wires. You can operate these at a higher speed because of the power generation process. These can deliver an extra amount of energy at lower speeds. When the coil spins inside a magnetic field, the current gets generated.

People use alternators to generate small-scale electricity. These can work as a charging system also for automobiles. You can use the generators to create large-scale electricity.

Verdict-

Besides, when it comes to reliability, the alternator wins the race. The generators come with brushes that wear very fast. It is because the generators use split rings. And due to this, the brushes have to rub them against the break. But for the first case, solid rings are used. Besides, the alternators can increase or decrease the voltage effortlessly. That is a big bonus.

These are also different when you compare these regarding the RPM range. RPM stands for Rotation Per Minute. The generators have a narrow range of RPM whereas the other one comes with RPM of a huge range.

The armature type for the generators is rotary. But the type of armature for the other one is stationary.

The last point that can differentiate these two is their EMF. The EMF is variable for the first case. But for generators, the EMF is constant.

Frequently Asked Questions

- What are the symptoms of a bad alternator?

The signs of a bad alternator are as follows:-

- The indicator light

- Headlights are dim or flickering

- Battery dies

- Strange noises

- Car stalls or has difficulty starting.

- Other electrical failures

- Can a car run without an alternator?

A car can’t be run when the battery dies. Without an car alternator, the car battery’s vital component will not get the required power. If it doesn’t, the entire function is disrupted.

- How do you tell if it’s your car battery or alternator?

When the engine dies instantly after starting, make sure that the car alternator is not charging the battery. In case a jump helps to start the car running, but the car is unable to start off using its own power, then a dead battery is a reason for your car.